A complete solution

We offer the complete solution including shank adapters, drill rods, drill bits, accessories and added value services.

Sustainable productivity

We continuously develop new, unique and energy efficient, products with the lowest cost of ownership.

Just about anywhere

We offer you tophammer equipment for every application, such as underground mining and tunneling, surface mining and quarries, and road and construction.

Tophammer drill strings for bench and production drilling.

- More drilling meters per day

Greater thread stability and quicker rod changes - Longer service life

Tougher rods and shank adapters also mean less breakages and longer service life - Quicker rod changes

Easy to uncouple thanks to the thread design

The Epiroc T drill string translates into a very real boost in productivity. Thanks to the increase in capacity, you’ll be drilling more holes per shift which opens up the possibility of quicker blasting. Wherever you work with production drilling, bench drilling or on construction sites you’ll notice the difference.

The Eprioc T drill string has a tough thread system. In fact, it’s robust enough to prevent product breakage in the blast hole. Which means you can shift your focus from all those time-consuming rod and shank changes to maintaining a much leaner stock.

Our drilling system comes in five dimensions: T35, T38, T45, T51 and Epiroc TW60. Epiroc T speedrods are ideal for bench and production drilling, and are available as extension or drifting drill rods. What’s more, the T range of shank adapters will work wonders with your equipment – whether you’re running an Epiroc drilling rig, or some other brand. Epiroc’s comprehensive range of tophammer drill bits matches the T drilling rods to perfection with the added benefit of being easier to release and change.

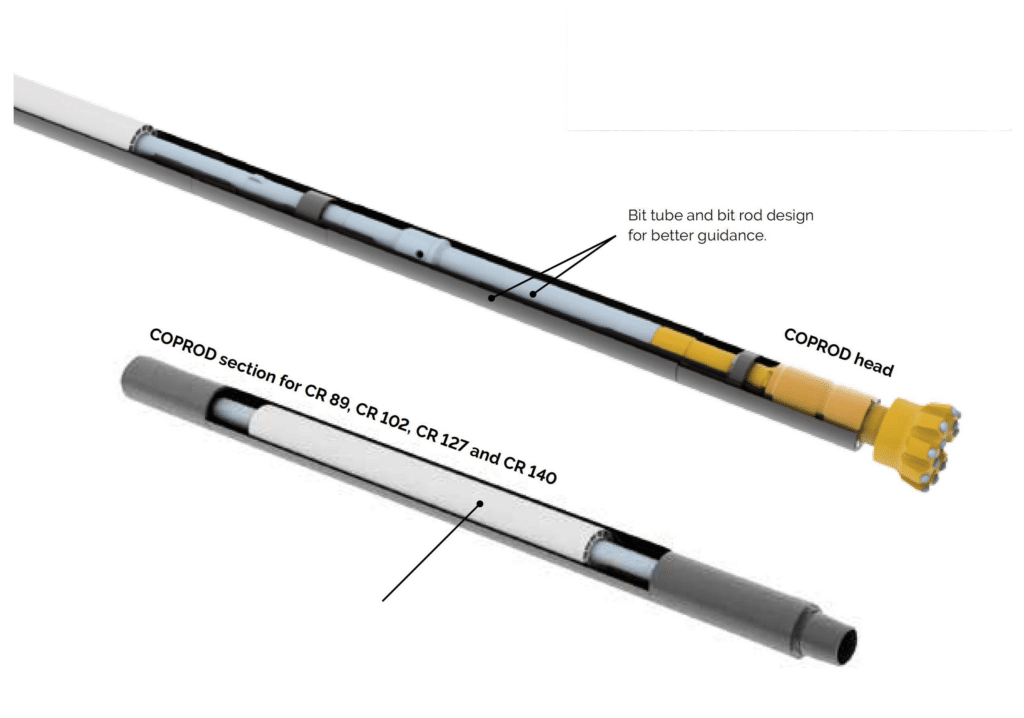

COPROD is a unique, patented rock drilling system from Epiroc. It combines the high penetration rate and low diesel consumption of tophammer equipment with the hole straightness and hole quality of DTH drilling.

COPROD combines a threaded drill tube with an unthreaded drill rod. The drill tube transmits rotation, while the impact rod, fit in floating suspension inside the tube, transmits impact energy and feed force. The flushing air passes

between the tube and the rod, through the bit rod, to the front of the drill bit. This is an ingenious

solution with plenty of benefits for you.

When the COPROD sections are joined, the impact rods stand on top of each other inside the drill tube. This means that the impact energy is directly transmitted to the rock without passing a single thread. The result? Superior energy transmission, reduced diesel consumption and minimised wear on the drill string.

COPROD is particularly well suited for demanding drilling operations in broken rock. It offers excellent hole straightness. But, most importantly,

it is possible to regulate air flow so that you don’t flush out more rock than necessary. The hole remains intact which means that the amount of explosives can be kept according to plan.

The SmartROC drill rigs built for COPROD, offer a unique feature. A special Rod Handling System (RHS), allows the drill string to be re-sorted for each hole. This means that the different sections of the drill string will be worn evenly over time.

For almost 40 years, COPROD has proved itself in the tough surface mining and quarrying industries. It has offered great productivity, and when it comes to the cost per ton of rock drilled, COPROD is second-to-none.

The COPROD product range consists of two surface drill rigs, and five different drill strings.

SmartROC C50 is the smaller of the two drill rigs. For this drill rig, three drill strings are available: COPROD 76 mm, 89 mm and 102 mm giving blast holes ranging between 90 – 140 mm in diameter.

The larger drill rig, SmartROC CL can be equipped with COPROD 102 mm, 127 mm or 140 mm drill strings. This means SmartROC CL can drill 115 mm to 216 mm blast holes.

Contact Haladjian Drilling Solutions

Please contact us with any questions. Customer service: epiroc@haladjian.com