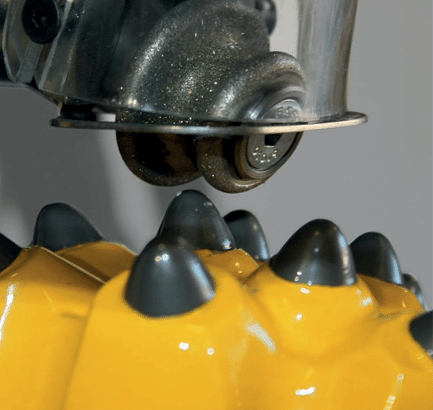

Drilling quality holes with maximum straightness and cost efficiency depends on a range of factors, not least the utilization and service life of button bits. Regrinding bits at regular intervals can make all the difference to the drill and blast lifecycle.

The button bit was originally developed to do the job of an insert bit, without the necessity for frequent grinding. However, it was soon found that the service life of a button bit increased considerably if the cemented carbide buttons were reground. Nowadays, it has become extremely important to grind button bits at fixed intervals, in order to extend the service life of the rock drilling tool, maintain penetration rates, and drill straight holes.

In all rock excavation operations, the cost is usually ex pressed in cost per drilled meter (cost/dm), in cost per cubic meter (cost/m3), or in cost per ton. The cost to produce a hole depends on how fast it can be drilled, and how many tools will be consumed. The cost of producing a cubic meter of rock depends on the cost of the hole, and the cost of blasting. If the blasthole is of poor quality, more explosives will be needed to blast the rock. Unsharpen bits result in very poor quality holes with deviation.

Grinding accounts for around 2% of the costs of the entire drilling operation. To run the business without grinding could multiply this cost, with up to 100% added when production losses are taken into account. Labor and material represent the highest costs, while machine investment cost is low when utilization is high, with a large number of bits to be ground.

Semi-automatic grinding machine for threaded and tapered button bits. High grinding capacity (full shift)

Semi-automatic grinding machine for DTH-and COPROD button bits. Can also be used for threaded and tapered button bits with optional accessories. High grinding capacity (full shift)

Handheld portable grinding machine for threaded and tapered button bits. Medium grinding capacity (10-25 bits/day)

Handheld portable grinding machine for DTH- and COPROD bits. Can also be used for threaded and tapered button bits with optional accessories. Medium grinding capacity (10-25 bits/day).

Our multi-grip holder widen your options for grinding different types of bit designs from small top hammer bits to larger DTH and COPROD drill bits. Medium grinding capacity (10-25 bits/day)

Contact Haladjian Drilling Solutions

Please contact us with any questions. Customer service: epiroc@haladjian.com