The SmartROC C50 from Epiroc gives you the best of both worlds. The rig combines high penetration rates with superior hole quality – even in the most challenging conditions.

The outstanding precision of the COPROD system provides you with optimal blasting results, increased safety and a sustainable outcome in the whole quarrying and surface mining operation.

- The superior precision in the drilling gives you optimal blasting results, increased safety and quality throughout the whole operation.

- The low fuel consumption, the low amount of energy loss and the long service life reduces your total running cost.

- SmartROC rigs deliver – shift after shift. We know what is important to you in the end: productivity and profitability.

| Main application area | Mining ; Quarrying |

| Drilling method | COPROD |

| Hole diameter | 90 mm – 140 mm |

| Product family | SmartROC |

| Cabin | Yes |

| Rock drill/ DTH hammer size | COP 3060 CR |

| Rotary head | DHR6 H 45 ; DHR6 H 56 ; DHR6 H 68 ; DHR6 H 78 |

| Maximum hole depth | 36 m |

| Engine | 242 kW |

| Air capacity (FAD) | 223 l/s |

| Note | Product variations apply. See brochure for more information |

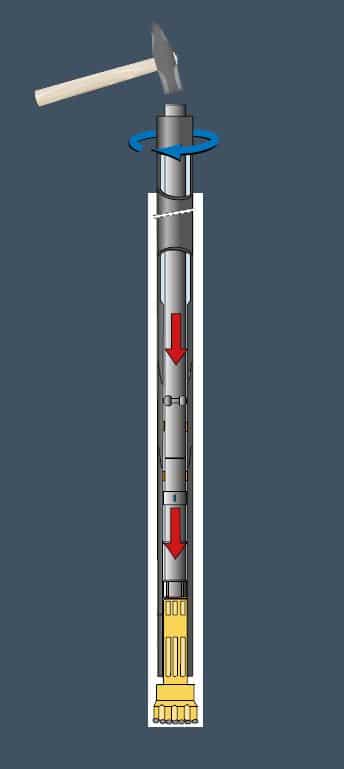

Compared to traditional drilling methods, our COPROD system has a longer service life. It’s also the most efficient way to transfer energy, as the unique dual string design allows more power to be transferred to the drill bit through the jointless inner rods.

Inside each rigid, threaded pipe section is an impact rod furnished with stop lugs to keep it in place. The COPROD sections are joined together via the drill pipes.

The drill pipes only transmit rotation force. All the nega-tive effects from transmission of impact energy through the threads is entirely eliminated. The result? High impact power with minimal wear.

The outer pipes are smooth and flush along the entire length of the drill string. This means it’s almost impossible for jamming to occur. The unique design of the COPROD head eliminates the rod guide and reduces air passage in the bit spline area to an absolute minimum. This prevents shank breakage, while the improved airflow reduces clog-ging in the bit. The drill bit is made of a new grade of steel with high impact and fatigue strength. In combination with the system’s low air pressure (12 bar), less airflow in the an-nulus space results in up to 50% longer life.